Features

The automatic instant noodle processing line is a new generation product with miniaturized production characteristics developed and produced by GELGOOG on the basis of researching similar products at home and abroad and combining with the needs of my country's mass consumer market. It is with perfect technology, compact structure, novel design and stable performance.

Capacity range: 11,000 bags, 30,000 bags, 60,000 bags, 120,000 bags, 160,000 bags, 200,000 bags/8hours.

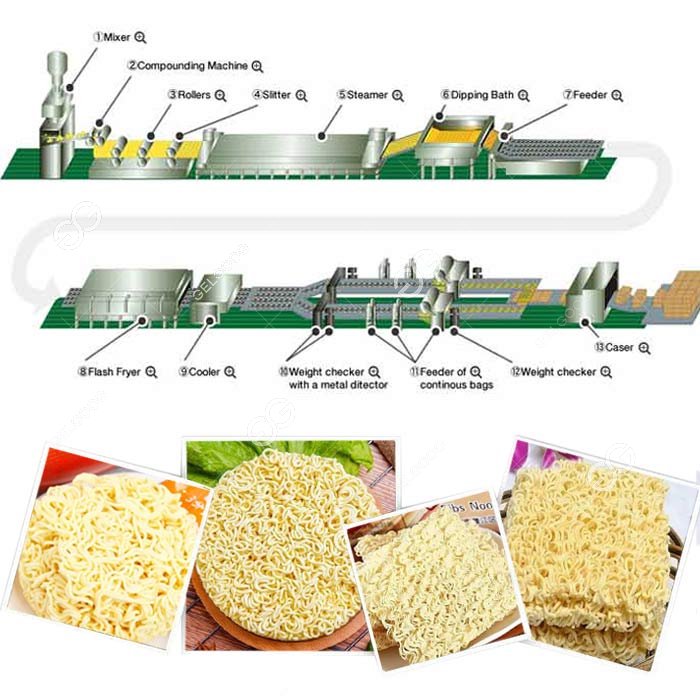

Production Process of Fried Instant Noodles Processing Line

Capacity range: 11,000 bags, 30,000 bags, 60,000 bags, 120,000 bags, 160,000 bags, 200,000 bags/8hours.

Production Process of Fried Instant Noodles Processing Line

Brine water mixing - Brine water measurement - Dough Mixing - Mixed flour curing - Dough Pressing - Instant noodles steaming - Instant noodles cutting and dividing - Enter into the frying box - Frying - Air cooling - Conveyor - packing (divided into bags and drums).

Fried Instant Noodles Production Line Configuration

1. Salt water mixer: Mix water with salt, alkali additives fully;

2. Salt water metering device: Meter water that needed for per pot flour, quantitatively control salt water into the dough mixer;

3. Dough Mixer: Fully mixing flour with water;

4. Curing machine: Aging flour, increase gluten value;

5. Dough pressing machine: Rolling, forming, splitting;

6. Steaming noodles machine: Make the instant noodles steamed;

7. Cutting dividing machine: Cutting, folding, dividing, form the instant noodles and into the box. Through different mold to produce square or round instant noodles.

8. Frying machine: Frying the instant noodles, make noodles more crisp, improve taste;

9. Instant noodles dryer: Suitable for non Fried instant noodles production, replace deep-frying technology, drying dehydration and fixed block shape;

10. Air cooling machine: Reduce the surface temperature, to meet the packaging requirements;

11. Conveyor: Convey finish instant noodles to each packing line;

12. Packaging machine: According to customer's production requirements matching sauce bag machine, powder packaging machine, vegetable bag machine, pillow packing machine (bags instant noodles), sealing machine for instant noodles bowl, heat shrinkable packaging machine for bowl instant noodles, folding &sealing machine, etc.

Reference Recipe for Instant Noodles:

Reference Recipe for Instant Noodles:

Flour: 200kg (special flour for instant noodles: moisture below 13.8%, protein 10.5-11%)

Salt: 4.5kg

Strengthening agent: 600g

Emulsifier: 500g

Pigment: 25g

Tapioca starch: 20kg

With more than ten years of R&D and export experience in the food machinery industry, GELGOOG has continuously introduced foreign technologies and innovated independently, so that the instant noodle processing line produced by the company has gradually reached the level of the food machinery industry at home and abroad. The entire instant noodle processing line is operated, the degree of automation is improved, and the service life is prolonged.

With more than ten years of R&D and export experience in the food machinery industry, GELGOOG has continuously introduced foreign technologies and innovated independently, so that the instant noodle processing line produced by the company has gradually reached the level of the food machinery industry at home and abroad. The entire instant noodle processing line is operated, the degree of automation is improved, and the service life is prolonged.

Technical Data

| Model | Output |

Noodle strip openting width |

Power |

Steam consumption |

Dimention (without packing machine) |

Plant requirement |

| GG-YZ250 | 11000 packets/8hours | 250mm | 140kw | Electric heating | L26m*W5m*H2.5m | L40m*W5m*H5.5m |

| GG-YZ330 | 30000 packets/8hours | 330mm | 55kw | 1-2t/h | L45m*W5m*H2.5m | L60m*W6m*H5.5m |

| GG-YZ350 | 60000 packets/8hours | 350mm | 55kw | 1-2t/h | L49m*W5m*H2.5m | L70m*W7m*H5.5m |

| GG-YZ450 | 80000 packets/8hours | 450mm | 60kw | 1-2t/h | L56m*W5m*H2.5m | L75m*W7m*H5.5m |

| GG-YZ510 | 100000 packets/8hours | 510mm | 85kw | 1-2t/h | L59m*W5m*H2.5m | L80m*W7m*H6m |

| GG-YZ550 | 120000 packets/8hours | 550mm | 85kw | 2-3t/h | L60m*W5m*H2.5m | L80m*W7m*H6m |

| GG-YZ650 | 160000 packets/8hours | 650mm | 105kw | 2-3t/h | L70m*W5m*H2.5m | L90m*W7m*H6m |

| GG-YZ800 | 200000 packets/8hours | 800mm | 138kw | 3-4t/h | L90m*W5m*H2.5m | L120m*W7m*H8m |

Related Posts

serena@gelgoog.com

serena@gelgoog.com

Customization Service

Customization Service

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail Whats

Whats TOP

TOP