Features

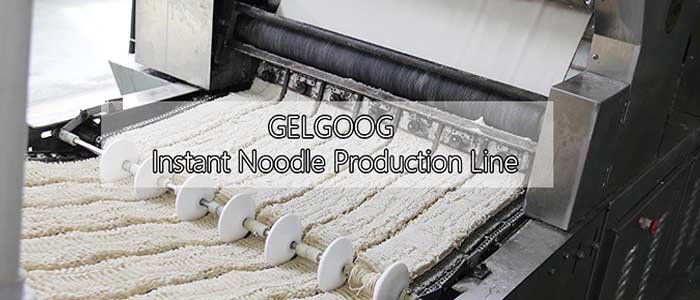

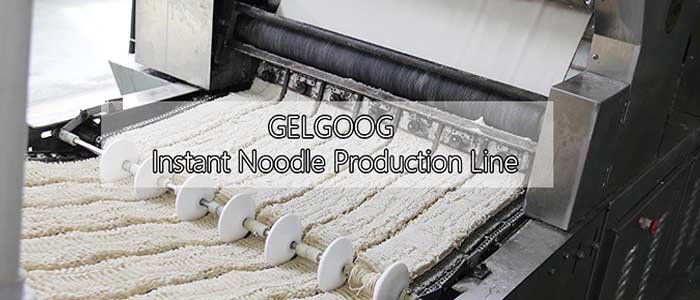

The instant noodle processing equipment produced by Gelgoog has high automation and mature technology, which adopts PLC control. It basically realizes full automation from mixing flour and noodles, rolling and laying flowers, frying and air cooling to packaging. The production line can realize the integrated production of square noodles, round noodles, bag noodles and cup noodles, which is more suitable for initial testing of emerging market needs.

Instant noodles have become one of the main food consumptions in modern times, which are characterized by convenience and diverse tastes, meeting people's needs for food. Our company specializes in the production of instant noodle machines, designs and provides different production equipment, fried and non-fried instant noodle production lines to meet the different needs of customers. At the same time, Jergoog provides complete supporting packaging equipment, automatic packaging, feeding, capping, and packing, which can realize the overall linkage and automatic operation.

Advanatges of Instant Noodle Processing Equipment:

1. PLC programmable control, high degree of automation, easy to operate;

2. Can provide product formula reference list and opinions, which can be adjusted according to specific needs;

3. The fryer is equipped with a coarse filter and a fine filter. The secondary filtration can prolong the oil change period and ensure the taste of the final product.

4. The production of two or even three products can be realized on one production line, which solves a lot of troubles for customers and saves a lot of costs.

5. According to customer requirements, professional technicians will be arranged to guide the installation and commissioning of equipment on site, and conduct operation training.

The instant noodle processing equipment produced by GELGOOG company is gradually at the level of the food machinery industry at home and abroad. The entire assembly line is operated, the degree of automation is improved, and the service life is prolonged. If you want to know more about instant noodle equipment configuration, site visit and other detailed information, please feel free to visit the factory at any time

Technical Data

| Model | GG-YZ350 | GG-YZ510 | GG-YZ650 | GG-YZ800 |

| Output | 60000bags/8h | 100000bags/8h | 160000bags/8h | 200000bags/8h |

| Dough Sheet | 350mm | 510mm | 650mm | 800mm |

| Power | 55kw | 85kw | 105kw | 138kw |

| Steam Consumption | 1-2t/h | 1-2t/h | 2-3t/h | 3-4t/h |

| Dimension | L49m*W5m*H2.5m | L59m*W5m*H2.5m | L70m*W5m*H2.5m | L90m*W5m*H2.5m |

| Factory Size | L70m*W7m*H5.5m | L80m*W7m*H6m | L90m*W7m*H6m | L120m*W8m*H8m |

| Workers | 5 | 7 | 7 | 10 |

Related Posts

serena@gelgoog.com

serena@gelgoog.com

Customization Service

Customization Service

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail Whats

Whats TOP

TOP