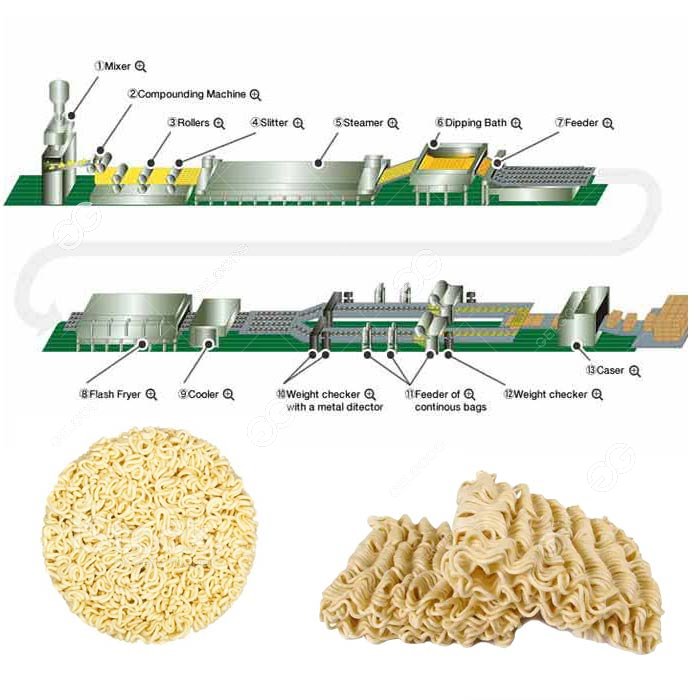

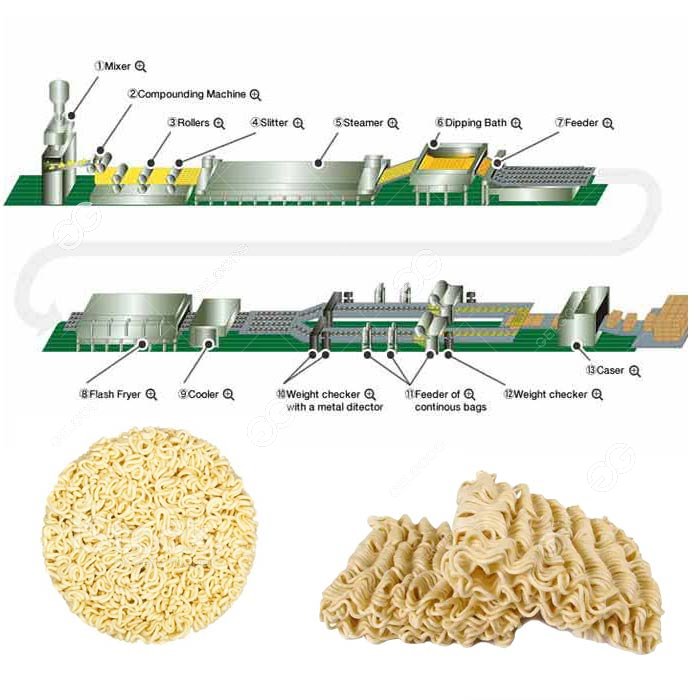

200,000 bags Instant Noodle Production Line Equipment List

Mar 28 2022

Mar 28 2022 Publisher:admin

Publisher:admin Source: gelgoog Machinery

Source: gelgoog Machinery

200,000 bag per shift fried instant noodle production line was sold to Nigeria, and following is the equipment list of this production line:

1, Brine mixer: 2 units

1, Brine mixer: 2 units

The motor power: 1.5kw*2 set, pump: 0.75kw*2 set

Mixing barrel capacity: 1000L*2 sets

Including: mixer, mixing barrel, heating tube, infusion tube, infusion pump.

Materials: stainless steel: mixing barrel, stirring shaft, heating tube, infusion tube, infusion pumps, valves.

Ordinary steel or cast iron: the drive units.

2, Brine Quantitative Measuring Tank: 1 set

Motor power: pump 0.75kw *1set

Features: Realize brine quantitatively feeding liquid automatically.

Volume: 130 L/time

Including: Quantitative barrels, stents, pipeline pumps, pipe fittings, valves, liquid level dosing device.

Materials: stainless steel

3, Two-axis Double Speed Mixer: 2 sets

Motor power: 13 kw/16 kw*2 sets

Features: two-speed mixing powder, pneumatic manual revolving door discharge, starting at low speed to high speed mixing and low speed mixing flour, to open the door automatic conversion.

Flour box specifications: 2000 mm long, and the powder quantity is 300 kg each machine.

Including: the hopper.

Materials: stainless steel: Dough mixing box, shaft, blades, hopper.

Ordinary steel or cast iron: Transmission parts, frame, cylinder.

Nylon: locating sleeve.

4, Disc Type Curing Machine: 1 set

Motor power: 4 kw

Raw material specifications: 2200mm*410mm Φ.

Materials: Stainless steel plate, pull rod, ram.

Ordinary steel or cast iron: Transmission parts and frame.

5, Compound Dough Pressing Machine: 1 set

Motor power: 7.5 kw (frequency control of motor speed).

Features: Drive side.

Roller 3 groups: Roller width 730 mm, diameter respectively are 270 mm, 270 mm and 300 mm.

Including: Guiding hopper, vertical plate, conveyor belt, roller clearance adjustment mechanism.

Materials: Stainless steel: Guiding hopper, flashboard, hood, side plate.

Copper: Scraper

Ordinary steel or cast iron: Transmission parts and frame.

Chilled alloy cast roller: Roller.

Edible rubber: Conveyor belt.

Nylon: roller plate.

6, Continuous Dough Rolling Machine

Motor power: 11kw+7.5kw+7.5kw=26kw(frequency control of motor speed).

Seven groups roller: Roller width is 730 mm, diameter respectively 270 mm, 270 mm and 248 mm, 248 mm and 216 mm, 180 mm and 180 mm.

Including: Press roll gap adjusting device, cutting knife, corrugated forming device, forming mesh belt.

Materials: Stainless steel: Forming net belt, corrugated forming device, hood.

Ordinary steel or cast iron: Transmission parts, frame, gap adjusting mechanism, cutting knife.

Chilled alloy cast roller: Roller.

Nylon: roller plate.

Roller to adjust the handwheel: Circular (handwheel center with dial).

Photoelectric sensor: Omron (control convey belt looseness between compound dough pressing and continuous pressing machine).

(forming mesh belt use dense mesh belt with the chain stay)

7, Single-layer Steaming Noodles Machine: 1 set

Power: 4 kw (frequency control of motor speed)

Point: Water seal, never leak, independent drive, no need to stop when adjusting noodles length.

Steam tank length: 32 meters

Including: Steamed tank insulation type, mesh conveyor belt, steam injection pipe, valves, pressure gauge, thermometer, exhaust 2 SET, 20 m (straight line) pipe, a section to open the door institution, axial flow fan 0.55 kw*2 sets, brush mesh belt equipment, oil brush equipment, 1 set inlet spray nozzle device.

Materials: Stainless steel tub, nozzle, conveyor chain, mesh belt, guide rail, exhaust hood, exhaust pipe.

Ordinary steel or cast iron transmission parts, plate, machine feet adjusting bolt, open up and down device.

Nylon: Nylon roll

Silicon aluminium acid: the body thermal insulation layer.

8, Instant Noodles Cutting Machine: 1 set

Motor power: 2.2 kw (VVVF), noodles off axis: 0.37 kw*1, circulating pump: 0.55 kw, blow water: 0.9 kw two, mixer: 0.75 kw.

Length: 4.9 m.

Features: Adopts planetary wheel differential mechanism, no need stop machine can unlimited adjust noodles piece uniformity. Equipped with liquid spray device.

Including: liquid spray device, circulating pump, blow water device, liquid trough, taste blender 0.5 m3.

Cutter forms: Rotary, cutter speed turn 60 r/min or less (adjustable).

Input lines: 9 line

Dividing frame: 9 line into 18.

Materials: stainless steel water pans, sealing plate, plate, liquid spray device, blow water device, liquid tank, mixing barrel, frame, fasteners.

Ordinary steel or cast iron: the drive units.

Silicone rubber: Dividing mesh.

9, Frying machine: 1 set

Motor power: host 5.5 KW(VVVF), horizontal circulation pump: 22 KW, lift motor 3 KW, oil fan blowing 0.9 KW*3 sets, gear pump 2.2 KW*1.

Frying machine overall length: 14 m, frying time about 90 s.

Heating method: Adopts the indirect steam heating (heating system working pressure: 0.8 Mpa or higher).

Including: 1 set 120 m2 spiral plate heat exchanger, 1 set oil circulation pump, 1 gear pump, 1 slag filter, Frying filter 1, 3000L oil storage box 2 set, automatic steam regulating valve, 1 set liquid level alarm, oil circulation pipes, valves, pressure gauge, thermometer, lifting gear on frame 1 set, noodles box, lifted the lid, conveyor chain, 20m moisture removal pipe, 2 oil pans.

Materials: stainless steel frying box, lifted the lid, outside sealing plate, pan Fried machine orbit, the lining, moisture removal pipe, oil pans.

Ordinary steel or cast iron: Transmission parts, body, oil tank, oil circulation pipes, valves.

Silicon aluminium acid: The body thermal insulation layer.

Note: The oil level of automatic control and the oil temperature control, three thermometer show oil temperature in the front, middle and latter, outside sealing plate and the chimney is made of stainless steel, all stainless steel except slag filter, the outer filter adopts the form of mesh belt.

At least 200 degrees high temperature liquid level display glass tube heat resistance. Frying oil pans in front of the machine also has a separate pump recovery unit, behind frying machine has instant noodles conveying turn-over device.

10, Noodles box switch: 1 set

Materials: the transmission, the frame body adopt quality carbon steel.

Including spare noodles box 1 set

11, Strong Air Cooling Machine: 1 set

Power: 1.5 kw, including noodles finishing machine, suction fan 3 kw*2, inlet air: 0.37 kw*14.

Air cooling form: Strong air cooling, central exhaust.

Including: Finishing machine, 9 meters changfeng groove, instant noodles track, scraping type dial rod conveyor belt, oil pan, two suction fan, fan blowing 16, 10 m exhaust duct.

Materials: stainless steel dial rod, orbital wiredrawing, oil pans, duct.

Carbon steel: Frame body, shaft, the chain, transmission parts.

Upper aluminum alloy glass sliding door, lower high quality carbon steel surface spray.

Nylon: Dial rod, wire drawing tube.

12, Horizontal vertical conveyor: 5 sets(2 Horizontal 3 longitudinal)

Motor power: 0.37 KW (VVVF)*5

Machine: Made according to the actual display size.

Materials: stainless steel shield, outer protection plate.

Ordinary steel or cast iron: Transmission parts, machine feet.

Rubber: high quality and durable conveyor belt.

Nylon: rubber roller.

13, Finished product conveyor: 3 sets

Motor power: 0.37 KW (mechanical stepless speed regulation)*3 units.

Machine length: 2 m

Including: conveyor belt, packaging tables.

Materials: stainless steel packing tables.

Ordinary steel or cast iron: Transmission parts, machine feet.

Rubber: conveyor belt

serena@gelgoog.com

serena@gelgoog.com

Customization Service

Customization Service

E-Mail

E-Mail Whats

Whats TOP

TOP