Features

We provide Fried instant noodles maker machine with factory price, this whole production line has unique production process, innovative design, high degree of automation.

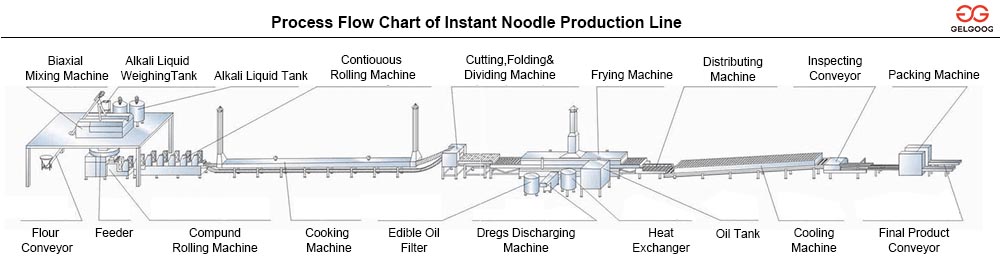

Instant Noodles Production Line Equipment List

Instant Noodles Production Line Equipment List

1, Alkali, salt water storage tank

2, Additive mixing cylinder

3, Spray controller

4, Operation platform

5, Double shaft dough mixer

6, Curing feeding machine

7, Compound dough press machine

8, Continuous dough rolling machine

9, Instant noodles steaming machine

10, Cutting folding machine

11, Dividing machine

12, Instant noodles fryer machine

13, Cooling machine

14, Checking conveyor

15, electrical equipment

1. There are Fried instant noodles production line and non Fried instant noodles production line for choice;

2. By changing the section configuration can produce square, circular instant noodles;

3. Can produce various specifications of instant noodles, surface weight ranged from 40 g to 120 g, production flexibility.

4. Parts contacting food USE the high quality food grade 304 stainless steel, ensure food safety, easy to clean.

5. PLC control, high degree of automation, simple operation.

6. Curing process and more roller pressing, make the instant noodles more dishes, taste better.

7. Steamed noodles machine, frying pot manual or automatic lifting, easy to operate.

8. Frying machine is equipped with a heat exchanger, guarantee the frying temperature constant, conducive to production quality control and improvement of the production process.

9. Oil frying machine is equipped with a filter out the bits, extend the oil change period, and make sure the taste of Fried noodles block.

10. Deep fryer with oil level automatic control function, save manpower, and convenient production control.

11. Components using well-known brands at home and abroad, to guarantee the quality.

12. According to existing customer plant, flexible design and production quality.

Technical Data

Paste width:650mm Capacity:160,000/8h(65g/pcs)

| Model | GG-YZ510 | GG-YZ550 | GG-YZ650 | GG-YZ800 |

| Output | 100000bags/8h | 120000bags/8h | 160000bags/8h | 200000bags/8h |

| Dough Sheet | 510mm | 550mm | 650mm | 800mm |

| Power | 85kw | 85kw | 105kw | 138kw |

| Steam Consumption | 1-2t/h | 2-3t/h | 2-3t/h | 3-4t/h |

| Dimension | L59m*W5m*H2.5m | L60m*W5m*H2.5m | L70m*W5m*H2.5m | L90m*W5m*H2.5m |

| Factory Size | L80m*W7m*H6m | L80m*W7m*H6m | L90m*W7m*H6m | L120m*W8m*H8m |

| Workers | 7 | 7 | 7 | 10 |

Related Posts

serena@gelgoog.com

serena@gelgoog.com

Customization Service

Customization Service

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail Whats

Whats TOP

TOP