Features

Instant Cup Noodle Production Line Introduction

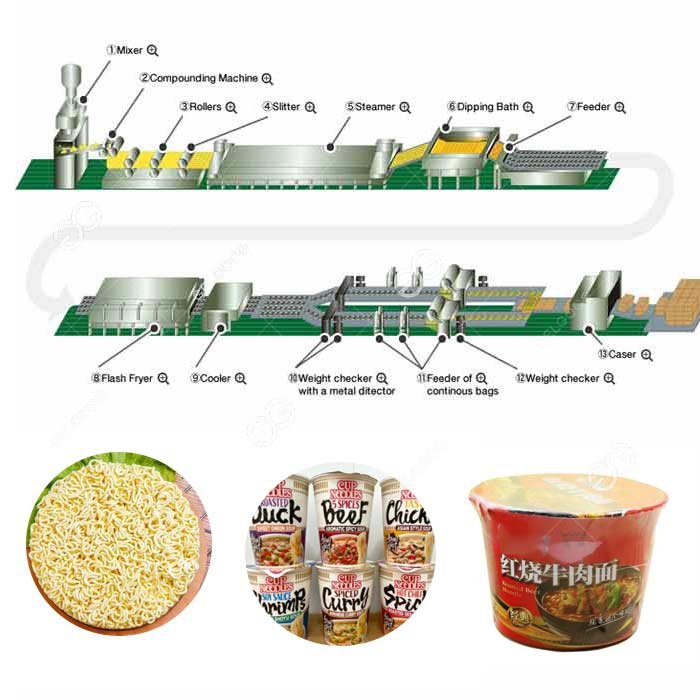

This cup noodle production line is a new instant noodle production line designed byGelgoog based on years of experience in the development of production equipment and foreign advanced technology. The production line has the characteristics of automatic production, large output, energy saving, compact structure, beautiful appearance, stable performance and convenient operation and maintenance.

The process of fried instant noodle production line includes brine mixing and metering system, noodles, cooking, pressing, steaming, frying, finishing, air cooling, conveying and packaging. The shapes of the noodle blocks that can be made are square and round, and the gram weight is determined by the customer's choice. The whole set of equipment is produced by automatic assembly line, such as automatic cutting, automatic folding, and automatic feeding into the frying box. The output is from 11,000 to 200,000 in 8 hours.

Bowl Instant Noodle Production Line Configuration

1. Salt water mixer: Fully mix water with salt, alkali and other additives.

2. Salt water metering device: Metering water that needed for per pot flour, quantitative control salt water from brine mixer into the dough mixer.

3. Dough mixer machine: Make water and flour fully mixing.

4. Curing machine: Curing mixed flour, increase gluten value.

5. Noodle pressing machine: Rolling forming, splitting and waving noodles.

6. Noodles steaming machine: Cook the instant noodles.

7. Cutting dividing machine: Cutting, folding, dividing, form the instant noodles block into the box, through different mold to produce square or round instant noodles.

8. Frying machine: Fried dehydrated and fixed block shape, make the instant noodles more crisp, improve taste.

9. Dryer: suitable for non Fried instant noodles, replace deep frying technology, drying dehydration and fixed block shape.

10. Air cooling machine: Cool the surface temperature, to meet the packaging requirements.

11. Conveyor: Deliver the produced instant noodles to each packing line.

This cup noodle production line is a new instant noodle production line designed byGelgoog based on years of experience in the development of production equipment and foreign advanced technology. The production line has the characteristics of automatic production, large output, energy saving, compact structure, beautiful appearance, stable performance and convenient operation and maintenance.

The process of fried instant noodle production line includes brine mixing and metering system, noodles, cooking, pressing, steaming, frying, finishing, air cooling, conveying and packaging. The shapes of the noodle blocks that can be made are square and round, and the gram weight is determined by the customer's choice. The whole set of equipment is produced by automatic assembly line, such as automatic cutting, automatic folding, and automatic feeding into the frying box. The output is from 11,000 to 200,000 in 8 hours.

Bowl Instant Noodle Production Line Configuration

1. Salt water mixer: Fully mix water with salt, alkali and other additives.

2. Salt water metering device: Metering water that needed for per pot flour, quantitative control salt water from brine mixer into the dough mixer.

3. Dough mixer machine: Make water and flour fully mixing.

4. Curing machine: Curing mixed flour, increase gluten value.

5. Noodle pressing machine: Rolling forming, splitting and waving noodles.

6. Noodles steaming machine: Cook the instant noodles.

7. Cutting dividing machine: Cutting, folding, dividing, form the instant noodles block into the box, through different mold to produce square or round instant noodles.

8. Frying machine: Fried dehydrated and fixed block shape, make the instant noodles more crisp, improve taste.

9. Dryer: suitable for non Fried instant noodles, replace deep frying technology, drying dehydration and fixed block shape.

10. Air cooling machine: Cool the surface temperature, to meet the packaging requirements.

11. Conveyor: Deliver the produced instant noodles to each packing line.

The entire instant cup noodle production line is highly automated, easy to operate, and saves time and labor. It has good production continuity, excellent product quality, high yield, and low energy consumption, and can be designed and produced according to customer requirements. GELGOOG can provide all the necessary equipment at one time, as well as a full range of instant noodle production planning services. Customized solutions according to your plant size, production plan, market expansion and other needs.

Technical Data

| Model | GG-YZ330 | GG-YZ350 | GG-YZ450 | GG-YZ800 |

| Output | 30000bags/8h | 60000bags/8h | 80000bags/8h | 200000bags/8h |

| Dough Sheet | 330mm | 350mm | 450mm | 800mm |

| Power | 55kw | 55kw | 60kw | 138kw |

| Steam Consumption | 1-2t/h | 1-2t/h | 1-2t/h | 3-4t/h |

| Dimension | L45m*W5m*H2.5m | L49m*W5m*H2.5m | L56m*W5m*H2.5m | L90m*W5m*H2.5m |

| Factory Size | L60m*W6m*H5.5m | L70m*W7m*H5.5m | L75m*W7m*H5.5m | L120m*W8m*H8m |

| Workers | 5 | 5 | 5 | 10 |

Related Posts

serena@gelgoog.com

serena@gelgoog.com

Customization Service

Customization Service

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible!

You can fill in the form below, submit your contact information and product requirements to us, we will contact you as soon as possible! E-Mail

E-Mail Whats

Whats TOP

TOP